Basic Info.

Model NO.

HH-Power Cable

Province

Guangdong

City

Dongguan

Transport Package

Film Packing

Specification

HH-Power Cable

Trademark

Hooha

Origin

China

HS Code

8479400000

Production Capacity

10sets/Month

Product Description

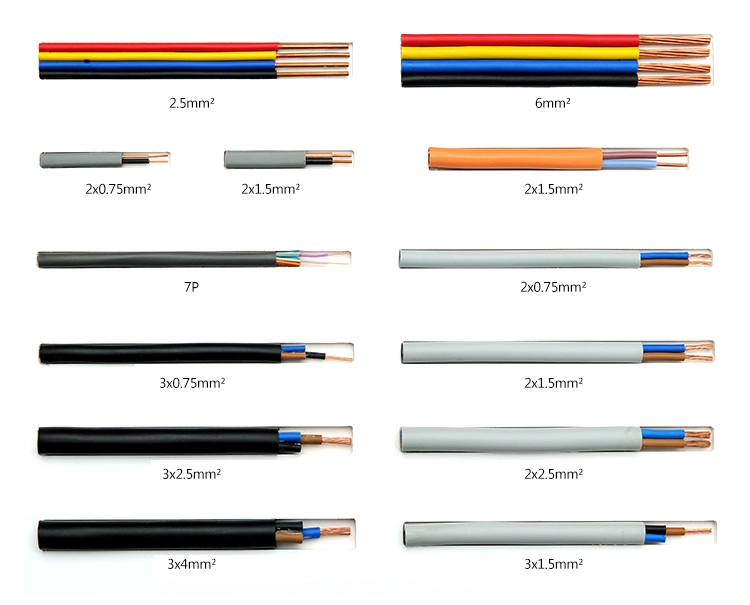

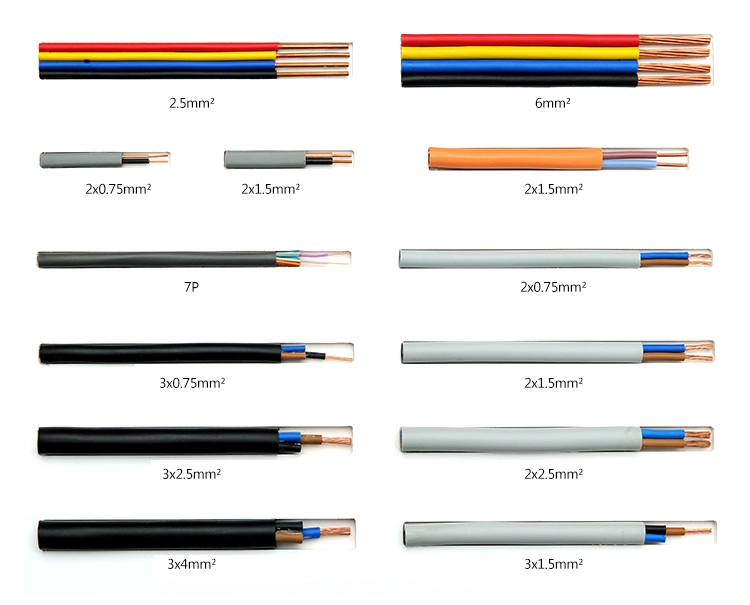

Hooha 1-16mm2 Power Cable Production Solution

Production Steps

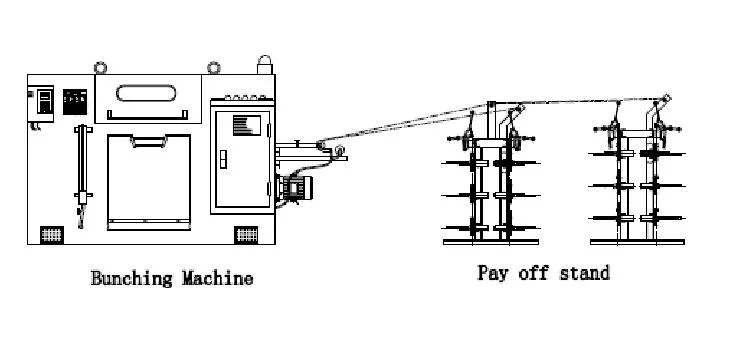

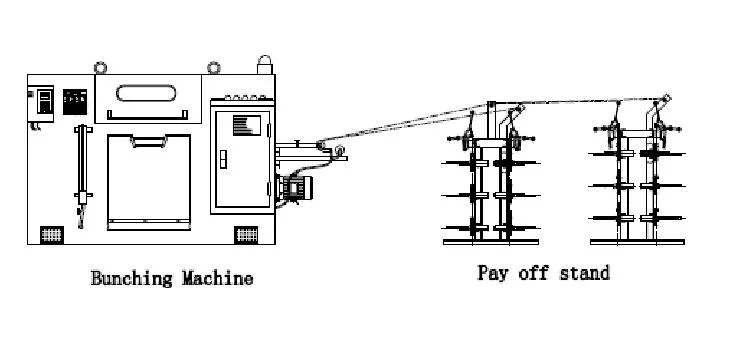

1. 630 High speed bunching machine for copper wire strand

2. 1000 High speed bunching machine for copper wire strand

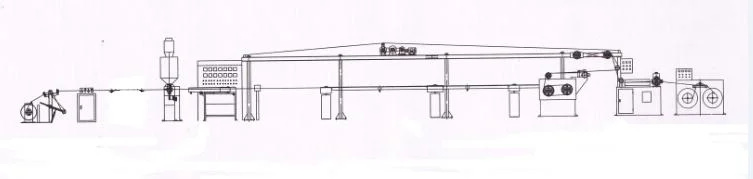

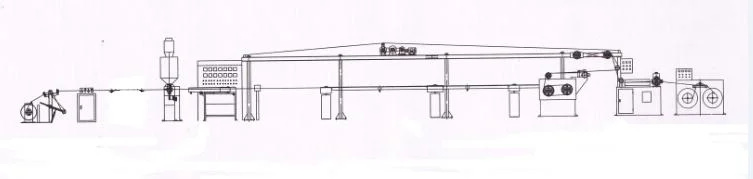

3. 70+40 Extrusion machine for wire Insulation

4. 90 Extrusion machine for wire Insulation

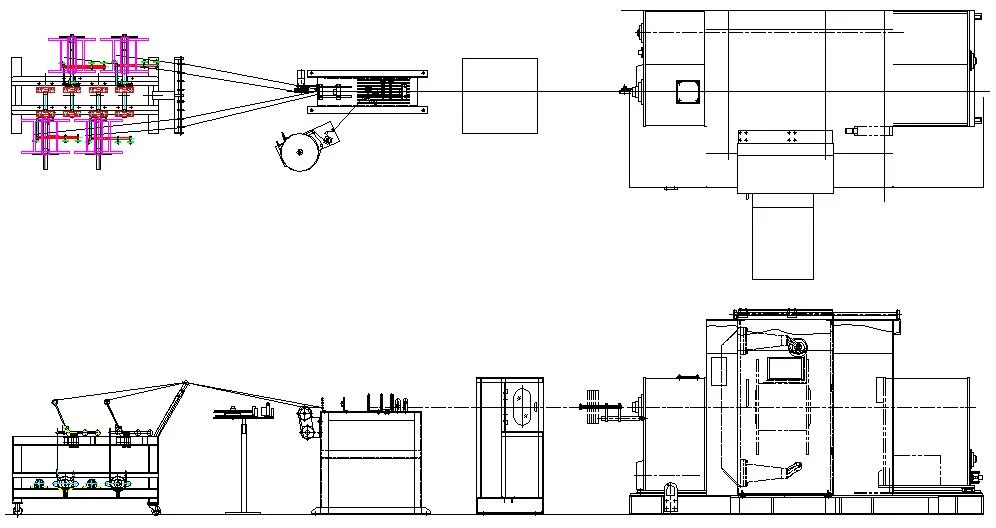

5. 1860 Wire coiling and wrapping machine for pack to coil

Application

It is suitable for stranding of the copper wires with more than seven strands, also suitable for electronic wires, power wires, bare copper wires, network wires etc.

Application

Application

It is suitable for the twisting and synchronous winding of insulated core wires such as USB cable, electrical cable, communication cable and data cable etc. This single twisting machine is widely used in various types of wires and cables production process.

the cable extrusion machine for linkage use.

Applicable Wire Range: 8-15mm

Power Supply: AC 380 V, three-phase, 50 HZ or customized

Operation Direction: Left or right side(Can be customized)

Packaged Coil Weight : MAX 50 kgWire Wire samples

It is suitable for stranding of the copper wires with more than seven strands, also suitable for electronic wires, power wires, bare copper wires, network wires etc.

Application

This equipment is applicable to outer surface extrusion of wires and cables with insulation materials such as PVC/PE.  Application

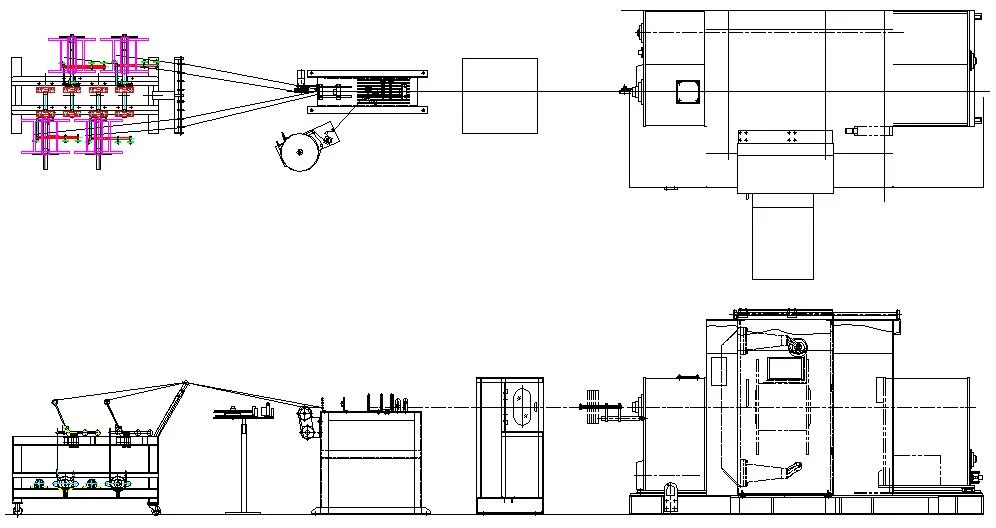

Application It is suitable for the twisting and synchronous winding of insulated core wires such as USB cable, electrical cable, communication cable and data cable etc. This single twisting machine is widely used in various types of wires and cables production process.

Application

This equipment is suitable for cable automatic coiling and wrapping, which would be packaged into a coil and can be connected tothe cable extrusion machine for linkage use.

Main parameters

Coiling Speed: 700 RPM

Coiling Size: Outside diameter: 220-600mm, height: 60-180mm, Inner diamete: 180-250mmApplicable Wire Range: 8-15mm

Power Supply: AC 380 V, three-phase, 50 HZ or customized

Operation Direction: Left or right side(Can be customized)

Packaged Coil Weight : MAX 50 kgWire

Our aim: To be a world-class supplier providing wire & cable manufacturing and using solution.

Our vision: To make wire & cable manufacturing and using more humanized.

Our target: More professional customer service, struggle for employees' dreams.

We are a Hong kong company, focusing on in-depth cooperation with Chinese leading manufacturers to provide advanced wire&cable solutions

Our vision: To make wire & cable manufacturing and using more humanized.

Our target: More professional customer service, struggle for employees' dreams.

We are a Hong kong company, focusing on in-depth cooperation with Chinese leading manufacturers to provide advanced wire&cable solutions

| Company name | HOOHA Co.,Ltd |

| Established | 2003 |

| Main products | upcast and continuous casting machine,wire extrusion machine,wire stranding machine,wire drawing machine,test machine and so on. |

| Value added service | Include factory planning, cable raw material supply,cable equipment layout,cable technology export,customer training and cable testing laboratory construction. |

| Factory location | Humen Town,Dongguan City,Guangdong province. |

| Manufacturing Center | 4000 sqm |

| Showroom | More than 2000 sqm. |

Hooha Technical Team

Pre-sale

1.Professional engineer team provide customized design and machine arrangement drawing service

1.Professional engineer team provide customized design and machine arrangement drawing service

2.Professional engineer team can visit customers's company in person and provide face-to-face service

3.Professional trading system provide high-efficient communication

Mid-sale

1.Professional follow-up system ensures high-quality service including live production video shooting,etc.

1.Professional follow-up system ensures high-quality service including live production video shooting,etc.

2.Quality control system with professional engineers ensures project goes smoothly.

3.Quality checking will be provided with professional quality inspection report before machine delivery.

After-sale

1.Free online consultance service.

1.Free online consultance service.

2.Long-time maintenance, reconstruction and upgrade services of the overall equipment.

Film packing

1. Materia: PE Film

2. Feature:

Low cost; Protect the machine;

Easy to disassemble;

Easy to packing;

Save container space

1. Materia: PE Film

2. Feature:

Low cost; Protect the machine;

Easy to disassemble;

Easy to packing;

Save container space

Wooden package

Enclosed Carton Packing

1.The CCA copper will packing anti the oxidation way

2.The PVC/PE/FEP packing will use the paper box and wood packing

3.The tape also use the paper box add wood package wooden package

1.Feature:

Improve the quality of packing;

Protect the machine in delivery process;

Good appearence

2.Usage:Machine packing

3.Type:Wooden tray; wooden box

Improve the quality of packing;

Protect the machine in delivery process;

Good appearence

2.Usage:Machine packing

3.Type:Wooden tray; wooden box

Enclosed Carton Packing

1.The CCA copper will packing anti the oxidation way

2.The PVC/PE/FEP packing will use the paper box and wood packing

3.The tape also use the paper box add wood package wooden package